Biggest British owned manufacturer of sheeting systems

Transcover is the biggest British owned manufacturer of sheeting systems in the UK, something that we are very proud of.

From our workshop in Aylesford, Kent, our Research and Development team trial and test materials to be used when bringing our designs to life. Our fabricators take the raw materials and turn them into usable parts that make up our sheeting systems. Machining assist fitment and the quality of every part to ensure durability and longevity. Our in-house Tarpaulin departments, in both Aylesford and Warrington, handcraft the tested material to meet the needs of the intended systems. All intricate parts and large assemblies are built by our Assembly team. To ensure that every kit, part and tarp arrives in perfect condition our Dispatch Team package and send everything we have made, working with trusted suppliers to get our products on the road.

It makes Transcover unique. We listen to the market and our customers, and can tailor our systems to meet specific needs, no matter the scale.

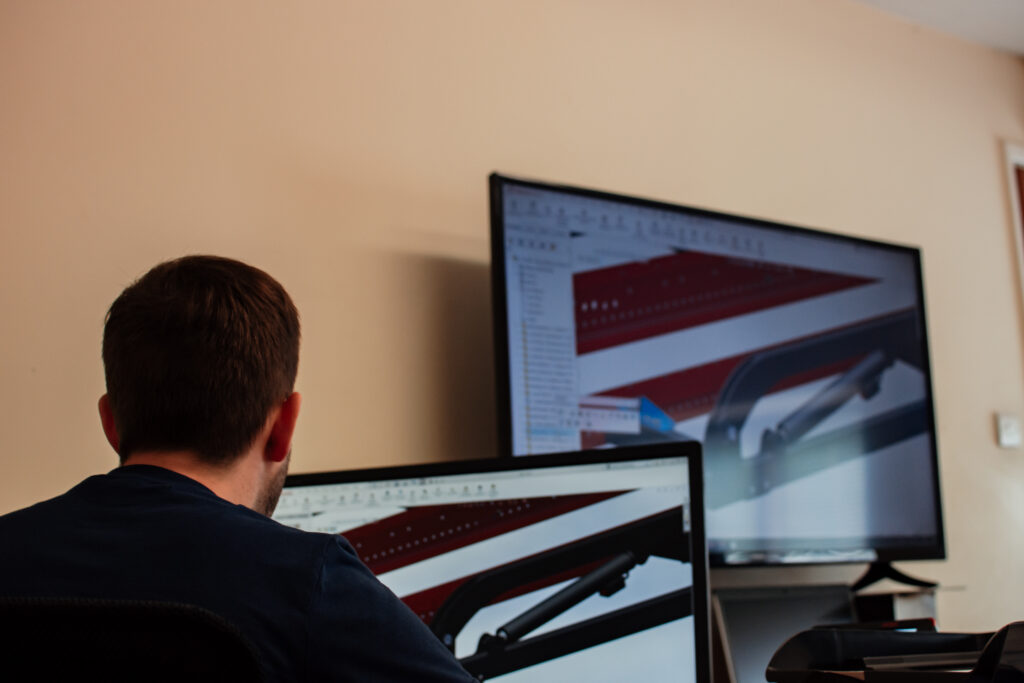

Design

Everything that leaves our warehouse starts with our Research and Development team. Every part of our systems are designed in finite detail to ensure that we meet our high standards of quality and durability. This includes selecting the right raw materials. Special care is taken to consider strength, weight, finish and sustainability, and our state-of-the-art software supports us in trialling and testing all materials.

Material

All the materials that arrive at Transcover are sourced from ISO2015 approved suppliers and quality checked throughout the manufacturing process. We build strong partnerships with our suppliers and have access to a vast catalogue of materials that meet our exceptionally high-quality standards. Access to the highest quality materials and our partnerships gives us complete creative freedom when it comes to designing new products and systems to meet the needs of our customers.

Fabrication

Our workshops are equipped to take materials from raw to road, fully finished, coated products ready to install or ship. Sustainable materials ensure we can keep our manufacturing line running efficiently, enabling us to produce kits, tarps and parts with significantly reduced lead times. Our Fabrication team is made up of highly skilled and experienced welders and folders. They are the best of the best, as proven by the exceptionally high quality of every element that leaves Transcover.

Machining

Part of the fabrication stage, the Machining team, work with raw materials, and get them road ready. Precision is key and using CNC machinery our team have the capacity to work to minimal tolerances to assist fitment and quality. Each run is quality checked and where needed coated for maximum durability and longevity.

Tarpaulin

Our in-house Tarpaulin team are based in both our Aylesford and Warrington workshops. Having our own team of experienced, skilled experts enables us to design and manufacture a sheet to any specification. We source high-quality materials, suitable for a variety of applications, from our market leading PowerMesh™ to our durable and economic Duramesh. All materials have been extensively tested for the field it is intended for, to ensure we are meeting the needs of our customers. Every tarp proudly displays the Transcover logo, marking the high-quality standards that it meets.

Powder Coating

To further improve our product lead times and gain further quality control on our finished products, our latest investment has been in our own powder coating plant. This not only means that we are able to manage the full product aesthetic but also fulfil our desire for complete raw to road manufacturing in-house, through our experienced team of experts at our Transcover workshops.

Assembly

Intricate parts and large assemblies are built in-house by our Assembly team. Everything from electrical components to spring assemblies, housing and towers, are all assembled and tested on-site. Every component used is certified by our procurement team to ensure that they comply with ISO standards. We take special car to ensure sustainable supply for items such as hoses, bolts and air cylinders.

Dispatch

Maintaining standards extends to ensuring that kits, parts and tarps arrive with our customers in the same high-quality that they leave our warehouse. Using our vast courier and shipping experience, our Dispatch team ensure that the packaging is fit for purpose. We have worked with our packaging suppliers for over 15 years and our strong relationship means our requirements are adhered to. We design crates, pallets and other packaging specific to our products’ needs.

Fitting

We have an in-house team of fitters who install our systems to vehicles, any make, any model, any size, any style. Our team can carry out fitting (and maintenance) at our Kent workshop or we travel to our customers, whatever is easiest. Customers not only receive the highest level of service but they are also offered the peace of mind that comes with knowing their system has been fitted and tested by an expert who understands every bolt, spring and cable that makes up our sheeting systems.

Raw to Road

Transcover are proud to be beginning to end, raw to road manufacturers. From sourcing the highest quality materials to designing packaging for dispatching final products, every member of the team plays an important role at maintaining the high standards and exceptional quality that has come to be expected when the Transcover logo is seen.

Being raw to road, British owned, UK manufacturers, it’s what makes Transcover different to our competition. We can tailor our systems to suit the specific needs of the market or our customer requirements. No matter how small or large the scale.